The DARTT Valve's construction utilizes high-strength stainless steel, heat-treated to resist friction, wear, and corrosion. It is available in most common pump sizes. Careful attention is paid to controlling the hardness of the piston to prevent damage to the ball, as well wear to the moving parts, ensuring the valve's longevity and reliability.

Order NowThe DARTT Valve's design leverages principles of hydraulic jump and sophisticated engineering to provide a solution for the challenges associated with plunger pumps, ensuring smooth and efficient fluid flow while maintaining durability and reliability even in demanding conditions.

Experienced oil professionals understand the challenges of ensuring efficient oil and gas extraction from wells. Each well has its unique story and behavior, which can change frequently. From gas lock issues to fluid pound, mechanical damage, and the need for regular pump changes, managing wells is an ongoing task. Sometimes, it costs more to maintain a well than the revenue it generates. To succeed in the oil industry, you need the best equipment, skilled operators, reliable pump shops, and insights from seasoned experts who can decipher subtle clues and apply their years of experience. The heart of any well is the downhole pump. While there are times when the pump may not deliver any fluid (liquid or gas), it's more common for it to pump at least some fluid. To achieve this, operators must address daily well challenges, analyze fluid levels, flow, pound, dynamometer card curves, and more. They use the best equipment and methods developed over a lifetime in the industry. Accountants then calculate production costs, subtract them from sales revenue, and provide data to management, which sometimes leads to well shutdowns or field sales – a situation that saddens everyone involved.

The reason a pump with a DARTT Valve operates while one without it doesn't is due to the physics of the traveling valve's operation. To unseat the traveling valve, you need force, which is the pressure within the pump during the downstroke multiplied by the area of the ball under the seat. This area is small, so the force is also small. The DARTT Valve, however, exposes six times the ball area to this pressure, resulting in six times the force to unseat the ball. This "six times" force, centered within the DARTT Valve, is then applied to the ball through the combined actions of an inclined plane and a lever and fulcrum point, significantly increasing the force to open the ball, about forty-eight times the original force.

This increased force allows the DARTT Valve to lift the ball early in the downstroke and keep it off the seat throughout, allowing everything in the pump barrel into the production column. By opening the traveling valve at the start of the downstroke, transient forces can't build up to affect the valve's operation within the DARTT Valve. If, for example, a grain of sand gets lodged between the ball and seat, the DARTT Valve's three valves would act as the traveling valve during the upstroke, and the following downstroke, the DARTT plunger action would unseat the ball, eliminating fluid wash damage and enabling the pump to operate during every stroke, regardless of sand or gas in the production fluid.

During the power stroke, the DARTT Valve remains in the down position, with all three valves closed, aiding in pulling a near-perfect vacuum. At the start of the downstroke, as the DARTT plunger moves upward toward the traveling ball valve, the bottom valve within the Dartt Valve opens, allowing fluid to push the DARTT plunger upward with additional force. When the DARTT plunger opens the top valve, fluid contacts the bottom of the traveling ball valve breaking the surface tension between the ball and seat. DARTT plunger uses momentum energy to deflect the ball, preventing damage. Fluid flow around the DARTT plunger keeps it in the upward position during the entire downstroke, ensuring the traveling ball remains open, preventing ball dance damage.

Opening the traveling valve early in the downstroke maintains a continuous volume from the standing valve to the surface within the production tubing, preventing gas pockets in the pump and fluid pound. It also acts as a lubrication source for the pump, helping avoid damage due to insufficient lubrication.

Because the DARTT Valve fully fills the pump every stroke, fewer strokes per barrel of fluid produced are required, reducing work, pump wear, and electric bills.

DARTT Valves cater to plunger pumps, tubing pumps, and traveling barrel pumps. To install a DARTT Valve, remove the plug retaining the ball and seat from the conventional double female traveling valve cage. Replace the plug with the DARTT Valve and tighten it following the standard cage tightening procedure.

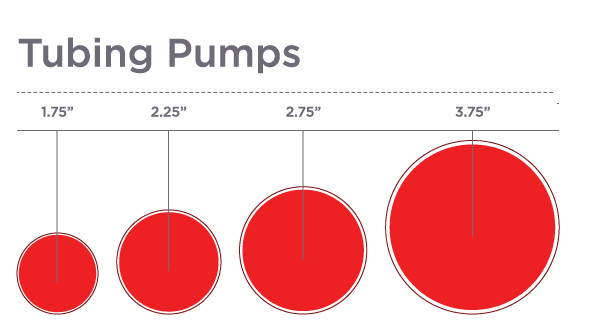

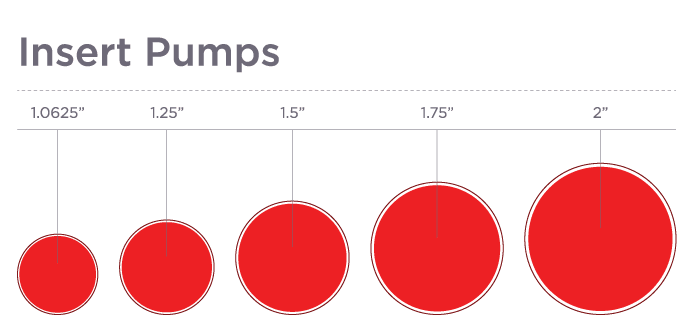

The DARTT Valve is available in the most common pump sizes and the standard metal type is 17.4 pH Stainless Steel:

Please note:

Install the valve on a single traveling valve cage.

Avoid using it on removable insert type cages.

Tubing pump applications have threaded bottoms for standing valve pullers

The DARTT Valve ensures optimal pump performance through innovative downstroke efficiency, hydrostatic upstroke reset, surface tension management, fluid stream control, durable construction, and efficiency-optimizing design.

Allows Longer, Slower Fully Loaded Pumping Strokes

Increases Liquid Production

Increases Gas Production

Allows Efficient Pumping Of Heavy Crude

Built For Durability

Sandy Conditions

Easily Installed

Will Not Damage Your Pump

Please note:

Our warranty guarantees the quality of every valve, addressing material and workmanship defects.

If a manufacturing defect arises, we promptly replace the valve with a new one.

External wear or corrosion is not covered under our warranty.

This statement comprehensively outlines the warranty terms, covering the product, both expressed and implied.