A breakthrough for enhancing the performance of your downhole oil pump.

The DARTT Valve, rooted in innovative design principles and hydraulic jump theory, guarantees optimal fluid flow and eradicates common operational challenges. Bid farewell to pump inefficiencies and elevate your oil extraction processes to unprecedented levels of excellence.

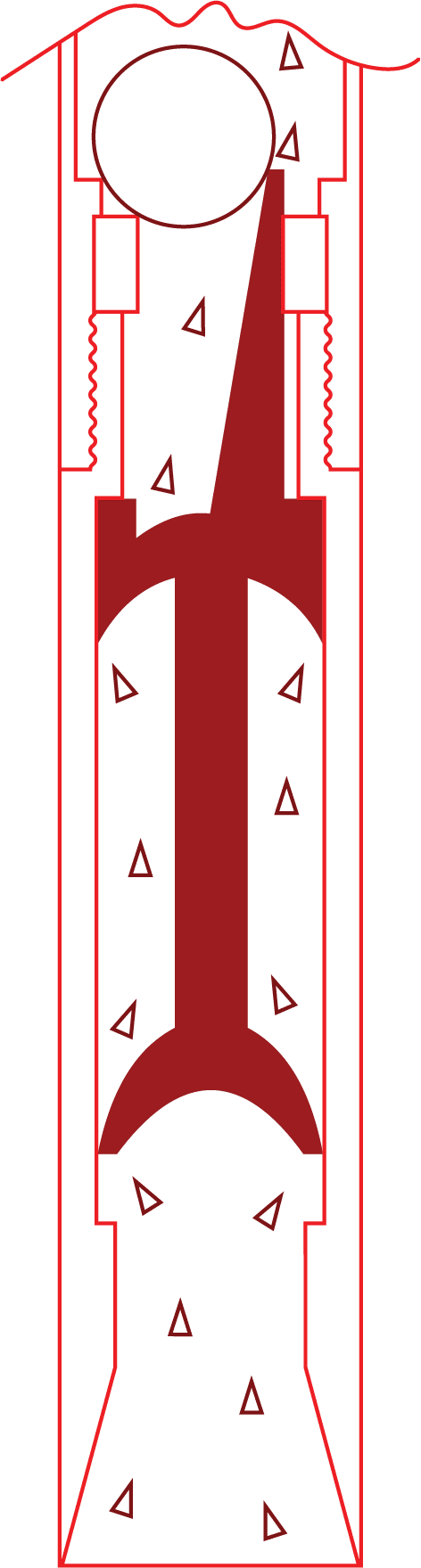

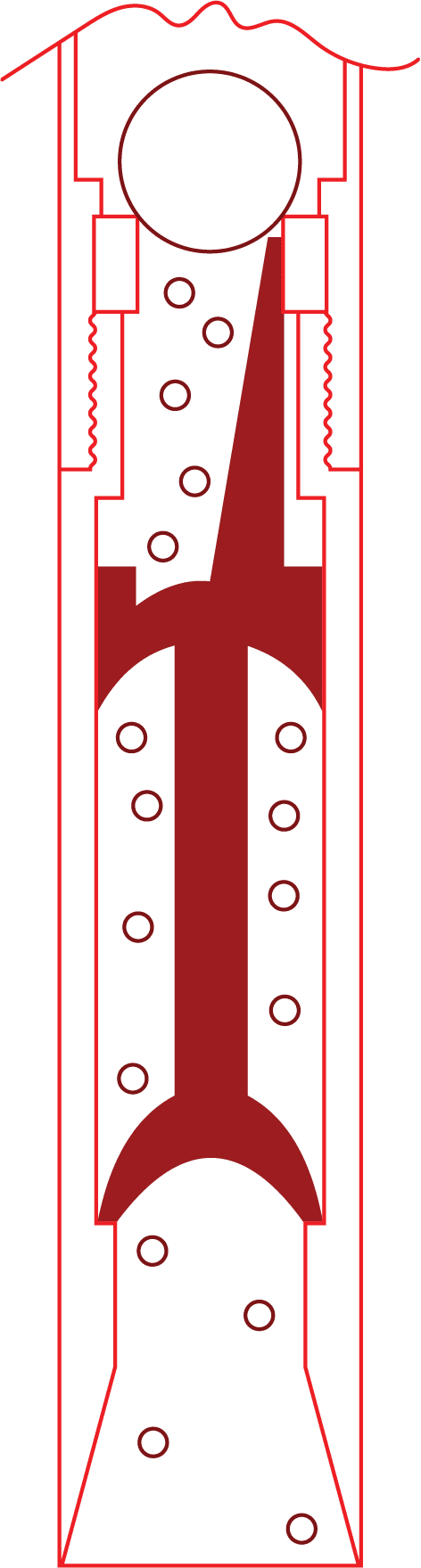

During the downstroke, fluid interacts with the DARTT Valve's intricate mechanisms, including a curved bottom internal piston actuator initiating the opening of the first valve, followed by umbrella-shaped discs directing the flow towards the second valve, and a metal object with a sloped tip channeling the flow to break surface tension, preventing gas lock or fluid pound issues for a smooth downstroke.

During the upstroke, hydrostatic forces drive the ball back into its seat, and the piston actuator returns to its seat position. This phase is crucial in resetting the DARTT Valve for the next downstroke cycle.

The DARTT Valve's efficiency and durability are improved through design elements such as a vertical groove on the metal object to break surface tension and a beveled top point acting as a screw to enhance fluid flow during the piston's motion.